Vacuum tables for Wood & Plastic Working

ST Series

The ST series vacuum tables are a simple construction of polyethylene and rolled aluminium.

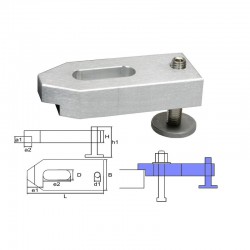

Clamping holes for M6 bolts with 50 mm separation distances are located within the vacuum surface for attachment.

They are therefore well suited for fixing on one of our T-slot plates or an adapter plate.

Due to their simple construction, the tables are a cost-effective solution and are not suitable for high-precision machining.

SEAL Series

This vacuum table series is an advanced version of the ST vacuum table.

A 8 mm strong aluminum plate at the bottom of the vacuum table provides extra stability.

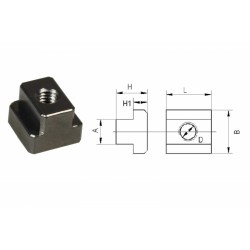

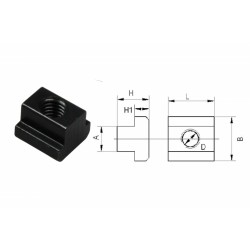

This aluminum plate allows you to fix the vacuum table on most T-Slot grids.

First you bolt the aluminum ground plate to the T-Slot bed, then you simply fix the vacuum table to the ground plate.

This provides a solid even base over the whole area. Typical areas of application are: Electronics, electrical engineering, engraving, model building, model making, plastic, wood and metal working, sign making and advertising technology.

At a glance the key advantages are:

- Use of high-quality materials; resulting in high long-term strength

- Wet machining no problem

- Almost distortion-free

- Very low construction height of only 29 mm; meaning no unnecessary working area loss for the Z-axis

- Working area is used right up to the edge; no bores economized on through exaggerated margin width

- Any number of vacuum tables can be attached directly to each other

- Adjustable connection adapter can accommodate both vacuum cleaner nozzles (between 28 and 44 mm) and hose nozzles

- Replaceable vacuum plate making it easy to repair in case of an accident

- Optimum vacuum distribution through extensive channels within the vacuum chamber

- High airflow through generously designed connections