Which vacuum pump should I use?

This is probably the most common question I am asked and can get quite confusing.

Here are 3 basic principles you can use to determine which vacuum pump will fit your needs:

- What size of vacuum table do you use?

- Which material are you working with (wood, metal, foil, plastic)?

- What are your machining practices?

What size of vacuum table do you use?

If you have a large vacuum table this doesn't necessarily mean you will need a large pump.

It all depends on what material you are going to be working with and the type of vacuum table you have.

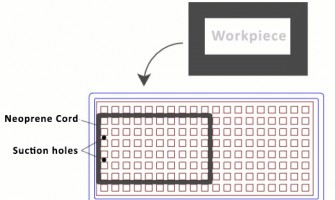

For example, our R Series vacuum tables include a foam rubber cord. Which ensures a tight vacuum seal with minimum air leakage. Therefore, a smaller vacuum pump would be required, such as our DST 8 or if you have access to compressed air then a Venturi.

Which material are you working with (wood, metal or plastic)?

Woodworking

When woodworking, you will typically have a large area to work with.

Perhaps you are making a door or window frame.

Since vacuum clamping works by total surface area and wood is very often porous you need a lot of airflow to clamp it down but you can clamp it with a lower given pressure.

In this case a centrifugal blower would be ideal. Due to its high air flow rate but at a lower pressure.

With a large surface area, when you apply the negative underside pressure with a vacuum you have a large positive downforce.

Therefore, since the vacuum needed is proportional to the surface area you can work well with a lower pressure pump.

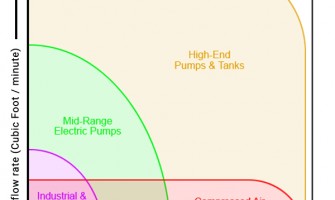

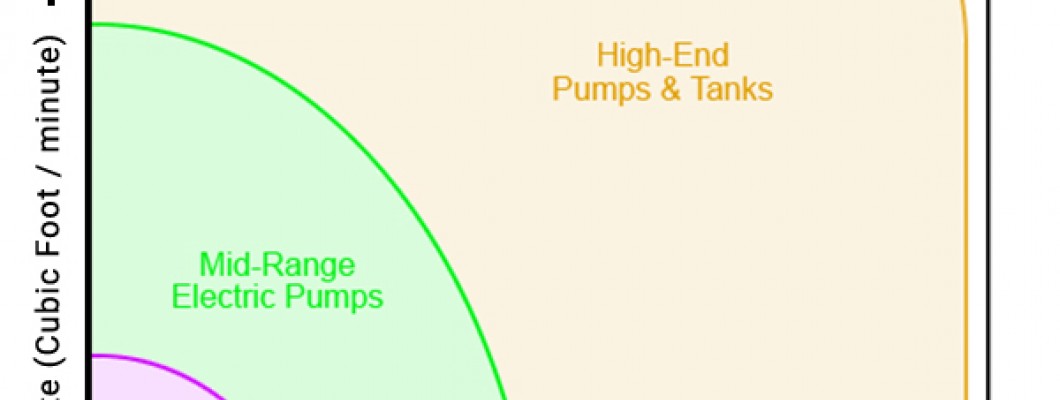

The diagram below shows the amount of air flow against which type of vacuum pump / generator you may require.

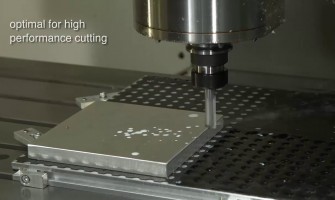

Metalworking

If you're working with metal it can be more difficult to decide which vacuum pump you need.

But in reality, there are only two main choices; a Venturi adapter or Liquid ring pump.

This is because most metalworkers use coolant when cutting, to protect the part they are working on and the expensive tooling.

You must use a higher-pressure pump as the forces required to cut metal are much greater than what you would expect with wood. Typically, metalworkers also work with smaller surface areas so they need a greater clamping force than a woodworker would expect to use.

Plastics

This very much depends on what type of plastic you are working with. And what level of accuracy and tolerance you need.

In fact, machining many plastics doesn't need a dedicated vacuum pump at all.

If you have a vacuum table with hose adapters, such as our SEAL or ST Series. You can easily connect to a standard vacuum cleaner or shop vacuum.

Another option is to use an all in one solution. Our VacEasy sets provide everything you need to get started.

What are your machining practices?

If you are engraving or just cutting into the material but not cutting all the way through, otherwise known as breakthrough milling, then a Venturi vacuum pump would be a good option as it is both cheap and gives a very good pressure rating.

The downside is you cannot break through mill which means you must leave a thin skin on the part, remove it after machining, break it out and manually or mechanically deburr it.

If you are looking to cut out complex shapes and patterns then a liquid ring pump would be the better option.

A liquid ring pump offers a very high pressure rating, but most importantly it is specifically designed to deal with lots of fluid so if you have a machining centre where you are flood cooling your parts when cutting.

The table below recommends our vacuum pumps best suited to your needs.

-

Product

Minimum vaccum pump

Optimale vacuum pump

VT2012ST

VTVE3

DST8

VT2020ST

VTVE3

DST8

VT2616ST

DST8

DST16

VT3020ST

DST8

DST16

VT4020ST

DST8

DST16

VT4030ST

DST16

DST25

VT4530ST

DST16

DST25

VT5030ST

DST16

DST25

VT5040ST

DST16

DST25

VT6040ST

DST16

DST25

VT2012GAL

VTVE3

DST8

VT2016GAL

VTVE3

DST8

VT3020GAL

DST8

DST16

VT2824GAL

DST8

DST16

VT4020GAL

DST8

DST16

VT3030GAL

DST8

DST16

VT4030GAL

DST16

DST25

VT4040GAL

DST16

DST25

VT5030GAL

DST16

DST25

VT5040GAL

DST16

DST25

VT5050GAL

DST16

DST25

VT6030GAL

DST16

DST25

VT6040GAL

DST16

DST25

VT6050GAL

DST25

DST40

VT7545GAL

DST25

DST40

VT7050GAL

DST25

DST40

VT8050GAL

DST25

DST40

VT8060GAL

DST25

DST40

VT10060GAL

DST40

DSN65

VT2818SEAL

DST8

DST16

VT2824SEAL

DST8

DST16

VT2132SEAL

DST8

DST16

VT4020SEAL

DST8

DST16

VT4432SEAL

DST16

DST25

VT6040SEAL

DST16

DST25

VT5050SEAL

DST16

DST25

VT6353SEAL

DST25

DST40

VT6060SEAL

DST25

DST40

VT10035SEAL

DST25

DST40

VT7747SEAL

DST25

DST40

VT10050SEAL

DST40

DSN65

VT8565SEAL

DST40

DSN65

VT10060SEAL

DST40

DSN65

VT2010RAL

VTVE1

VTVE2, DSN8

VT2020RAL

VTVE1

VTVE2, DSN8

VT2815RAL

VTVE1

VTVE2, DSN8

VT3020RAL

VTVE2

DSN8

VT5015RAL

VTVE2

DNS8

VT4220RAL

VTVE2

DSN8

VT5040RAL

VTVE3

DSN8

VT7535RAL

VTVE3

DSN8

VT6040RAL

VTVE3

DSN8

VT7545RAL

VTVE3

DSN8

VT12080RAL

VTVE3

DSN8

VT1212smart

VTVE1

VTVE2, DST8

VT2012smart

VTVE1

VTVE2, DST8

VT2020smart

VTVE2

DST8

VT3020smart

VTVE2

DST8

VT3030smart

VTVE2

DST8

VT4030smart

DST8

DST16

VT4530smart

DST8

DST16

VT4432smart

DST8

DST16

VT5030smart

DST16

DST25

VT5040smart

DST16

DST25

VT6040smart

DST16

DST25

VT2012GR

VTVE3

DST8

VT3020GR

DST8

DST16

VT5020GR

DST8

DST16

VT4030GR

DST16

DST25

VT5040GR

DST16

DST25

VT6040GR

DST16

DST25

VT7050GR

DST25

DST40

VT6050GR

DST25

DST40

VT10050GR

DST40

DSN65

VT10060GR

DST40

DSN65

VTDIN-A5FAL

VTVE3

DST8

VTDIN-A4FAL

DST16

DST25

VTDIN-A3FAL

DST16

DST25, Rubin90

VTDIN-A2FAL

DST25

DST40, Rubin90

VTDIN-A1FAL

Rubin90

Rubin220

VTDIN-A0FAL

Rubin220

Rubin340

VT2420FAL

DST16

DST25

VT4020FAL

DST16

DST25

VT6040FAL

DST25

DST40, Rubin90