What vacuum table do I need?

This is a very common question I am asked.

The simple answer is it just depends on what you are CNC machining and what results you wish to achieve.

There are many tables that suit different types of work.

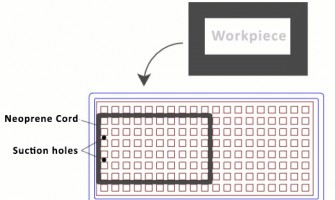

If your work never requires you to be cutting parts out completely then a grid style table is the perfect choice.

But if you think you’ll need to cut complex parts then you will need a hole matrix table, such as the GR Series.

What are the advantages of grid tables?

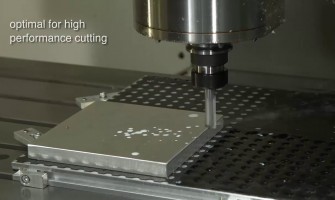

Grid tables such as the R series are perfect for engraving and cutting shapes into material.

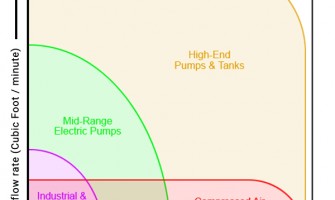

A good feature of these tables is you can use a simple Venturi or compressed air vacuum generator.

Perfect for keeping costs down if you’re a beginner wanting to get into vacuum clamping or in an industry where you have access to compressed air.

A Venturi adaptor is a cost-effective way to generate a vacuum without spending more money on a dedicated vacuum pump.

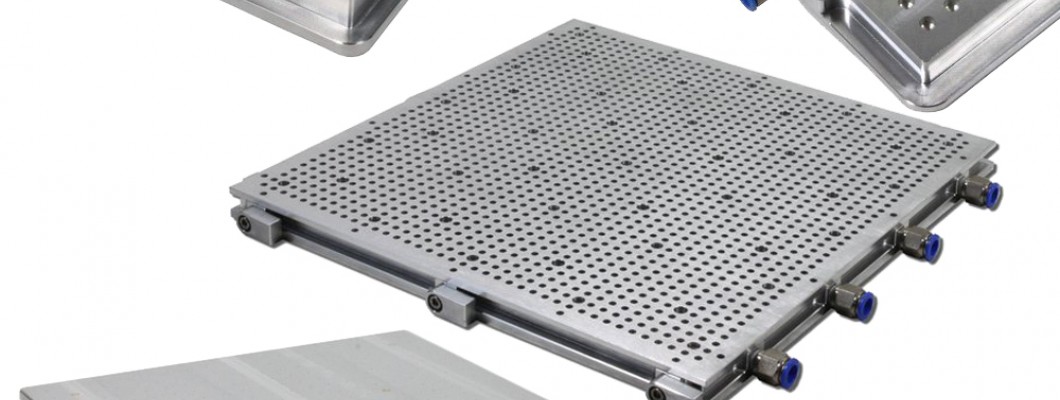

What are the advantages of hole matrix tables?

Hole matrix vacuum tables offer more flexibility than the grid tables.

And do mean you can cut all the way through with no worry about leaving a thin skin on the tables as you can cut your parts out in one procedure.

These tables must be used with a separate dedicated vacuum pump, a Venturi is no use with hole matrix tables. A Venturi adaptor works brilliantly where there is no air leakage in the part but as soon as there is they do not perform well.

The GR Series, GAL Series, ST Series or SEAL Series are the best type of table for CNC machining but are also very demanding on a vacuum generator.

To offset the air leakage from the parts you must have a vacuum pump capable of delivering a large amount of airflow and a constant high pressure to keep the workpiece in place.

Dry running, vane type rotating vacuum pumps (DST 16 upwards) are ideal.