How does vacuum clamping work?

The Basic Principal of Vacuum Clamping

First of all we find the normal atmospheric air pressure inside and outside of the vacuum

table, which withholds approximately 1 bar. Next some equipment (or workpiece) is placed on

the vacuum table’s surface and the remaining free space and drilled holes are covered with

rubber mats. And thus the air in the interior of the vacuum table can be drawn with a

vacuum pump. According to the vacuum pump, a pressure difference between the interior and

exterior emerges from approximately 100mbar to about 950mbar, and the boundary layer is

thus represented by the piece of equipment (or workpiece) found on the vacuum table.

As an example, lets say you take a pressure difference of 500mbar. Now depending on the

sealing method used with a 200 x 200mm vacuum table the result would be a surface pressure

of a maximum 200kp with the equipment or workpiece fully covering the whole table surface.

Since one of the most important things in mechanical preparations is to secure the

equipment or workpiece from slipping or moving out of place, it would make sense that you

place a mat or some type of material in between the equipment (workpiece) and vacuum plate.

Its also good to make sure that this material is airtight and that it also has a high

frictional resistance. Depending on the type of vacuum straining, there are various different

procedures available here that can guarantee an optimal solution depending on your specific

needs.

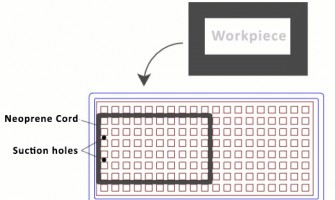

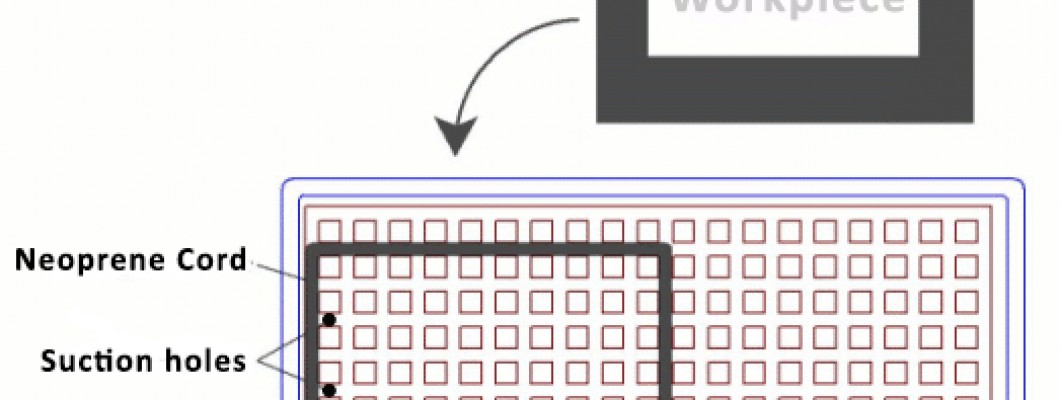

The Grid(Raster) Vacuum Table (RAL-Series)

The surface of a grid (raster) vacuum table consists solely of armatures, that are

connected to a few drilled holes with the vacuum pump. When inserting a rubber cord

into the armatures one can create a limited boundary around the drilled holes. This limited

boundary or field, should correspond to the desired workspace. Now the workpiece or equipment

can be placed and the vacuum can be started.

Advantages:

- The workpiece or equipment does not necessarily need a even underside. With considerable unevenness, approximately one millimeter can be balanced out by the rubber cord. For more difficult tasks, rectangular rubber cords are also available.

- Since the workpiece (equipment) pushes the rubber cord into the armature, its underside lies directly on the aluminium surface of the vacuum table, creating absolute accuracy.

- Since the system remains sealed during the whole operation, one must not demand so much work to be created from the vacuum pump. Very small outputs of 80-95% of vacuum are sufficient, therefore this procedure becomes very economical.

- Uniform oscillations and a delay free layer of the whole underside of the workpiece (equipment).

Disadvantages:

This procedure can only be used if no openings have to be milled, this is because if it’s

not sealed then this will cause immediate decrease of retention force.

Alternative:

A further possibility to operate a grid (raster) vacuum table is to produce an adapter mat

suitable for the respective workpiece (equipment). This can be produced out of various

materials e.g: hard rubber, rubber and soft-PVC. The thickness depends on the

respective armature gaps and widths. This adapter has openings only where the

workpiece (equipment) must be held, and is sealed in the places where the milling machine

passes through.

Advantages:

- Openings do not lead to leakage and therefore are no problem.

- Maximum retention force with minimal demands required for the vacuum pump.

- The workpieces (equipment) do not require post-processing, because their whole contour can be worked on using a basic approach all around.

- No paths must remain standing.

- The most suitable process in a series (batch) production of smaller parts.

- Uniform oscillations and a delay free layer of the whole underside of the workpiece (equipment).

Disadvantages:

Manufacturing an adapter mat is just additional expense and effort, that is really only

worthwhile in a series(batch) production. Nevertheless the adapter mat can quickly

be made with simple tools, for example a scalpel or drilling machine, since it’s not

necessary to follow the course of the workpiece (equipment) contour exactly.

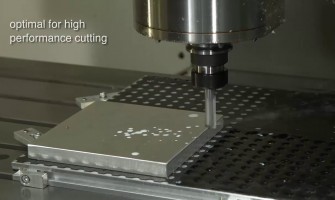

The Hole Grid (Raster) Vacuum Table (SE-Series)

Here there is a grid out of drilled holes distributed in a relatively narrow distance over

the entire surface of the vacuum plate. Sometimes these drilled holes are carried out as a

combination between a sack hole with a large diameter and a clearance hole with a

relatively small diameter. This has the advantage, that with the help of register pins

a proper repositioning workpiece(equipment) is possible.

Disadvantageously this technology merely works with the clamping of thin-walled or frail

workpieces (equipment), since above the sack holes they dent themselves in the vacuum. For

such uses, only vacuum tables with small suction drilled holes can be used. With a hole

grid (raster) vacuum table at first it’s not even attempted to completely seal the table,

but one assumes that after placing the workpiece (equipment) on the vacuum table and covering

the remaining surface that a certain amount of drilled holes will remain open. The

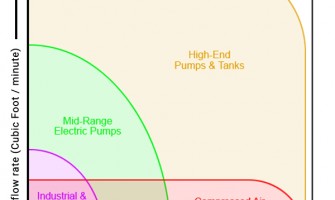

vacuum pump works here with a large volume with a slight differential pressure. This

operating principle enables openings during the processing of up to about 15% of the surface.

Due to the increase of frictional resistance either a hole rubber mat, where great accuracy

is required in the Z-Direction, or a sinter rubber mat as a cheap alternative for the cases

where simple cutting is sufficient.

It goes without saying that an adapter mat can also be using during this process. However, to

be able to work in completely the same way with a grid (raster) vacuum table, a vacuum

pump with high differential pressure is required. Should this however also be used for other

clamping techniques by means of a adapter mat in connection with a hole grid (raster)

vacuum table, it must as mentioned dispose over a large suction volume. Both together, the

high pressure and high volume however place very large demands on the performance of the

vacuum pump.

Advantages:

- Simplest clamping with light demands on the vacuum pump. First attempts using a simple household vacuum cleaner are very significant.

- Milling up until a certain point of the entire clamp surface is without a problem doable. This even works with the use of stop pins if a hole rubber mat is used.

- Full surfaced, sparing and low vibrating workpiece (equipment) support.

- With a series (batch) production using adapter mats to cover free areas is considered economical use.

- Large flexibility is created with register pins with the workpieces (equipments) support.

Disadvantages:

- Small workpieces (equipment) are only economically machinable if these are retained above paths.

- The vacuum pump has large energy demands (min. 4kw/m²).

- Slighter retention force by larger leakage than with a grid (raster) vacuum table.